Energy storage systems: Leading with safety

Safety is our #1 core value at Lightsource bp, guiding all that we do from project development through construction and operations. Our battery energy storage system (BESS) projects are no different. Keep reading to learn how we ensure safe and reliable energy storage systems in the USA.

Energy storage is regulated and reliable

Like all electrical infrastructure, utility-scale battery energy storage systems are highly regulated, with rigorous codes and standards developed by international, U.S. and local experts. Utility-scale batteries that deliver energy into the grid must be certified and go through extensive testing before being deployed, with requirements far beyond those for most commercially available batteries used for consumer applications.

We design, construct and operate our energy storage systems in accordance with all relevant national and international standards and procedures, proven to keep these sites safe. These include the International Fire Code (IFC), International Building Code (IBC), International Electrotechnical Commission (IEC), and National Fire Protection Association (NFPA).

Codes and standards

Click each item to learn more about some of the key codes and standards for utility-scale energy storage projects.

-

NFPA 855: Standard for the Installation of Stationary Energy Storage Systems

Standard provides the minimum requirements for mitigating the hazards associated with energy storage systems, which include safety requirements for BESS technology and equipment, as well as fire testing protocol.

Resource: American Clean Power Fact Sheet

-

International Fire Code

Code contains regulations to safeguard against fires and other hazards and addresses general precautions, emergency planning and preparedness, fire department access and water supplies, automatic sprinkler systems, fire alarm systems, special hazards.

-

UL9540: Energy Storage Systems and Equipment

A safety standard for energy storage systems and equipment intended for connection to a local utility grid or standalone application.

Resource: American Clean Power Fact Sheet

-

UL9540A: Test Method

Method delineates procedures for testing the fire safety hazards associated with propagating thermal runaway within battery systems, including testing at the cell, module, unit and installation level.

Resource: American Clean Power Fact Sheet

Responsible BESS design and safety

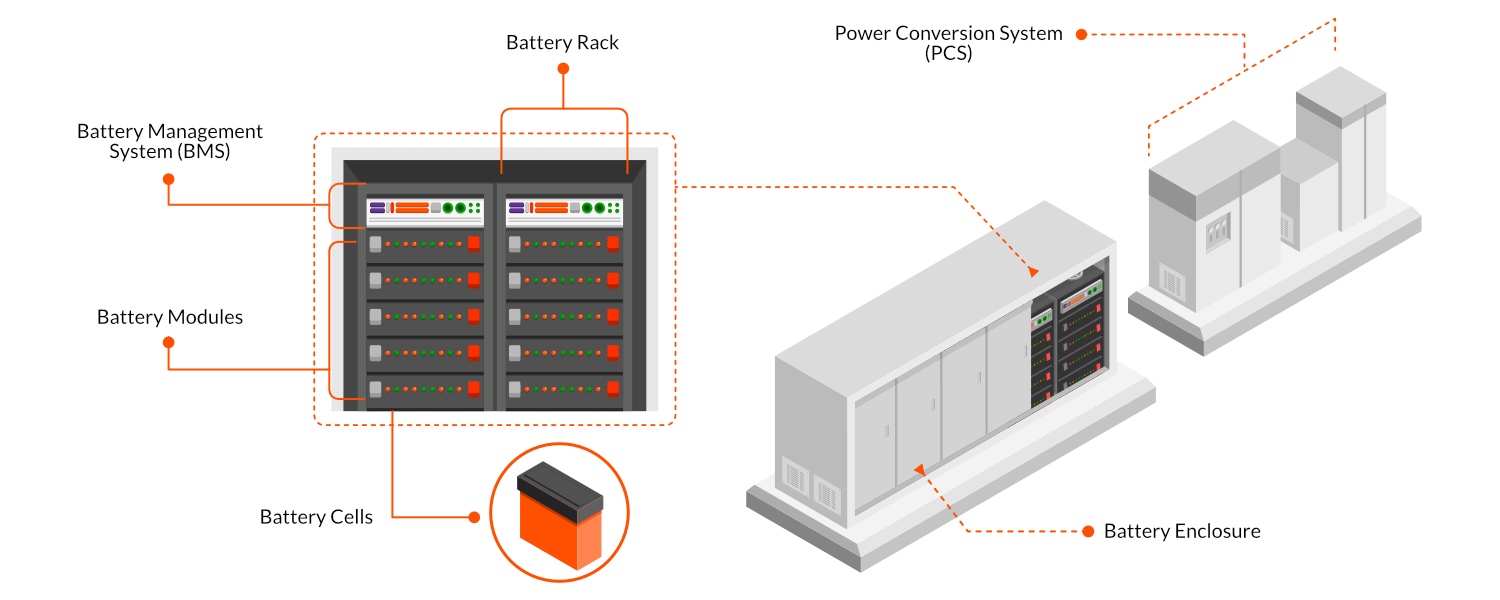

System overview

Components of a typical utility-scale battery energy storage system are shown here. For more in-depth information refer to Battery Energy Storage Systems (BESS) 101.

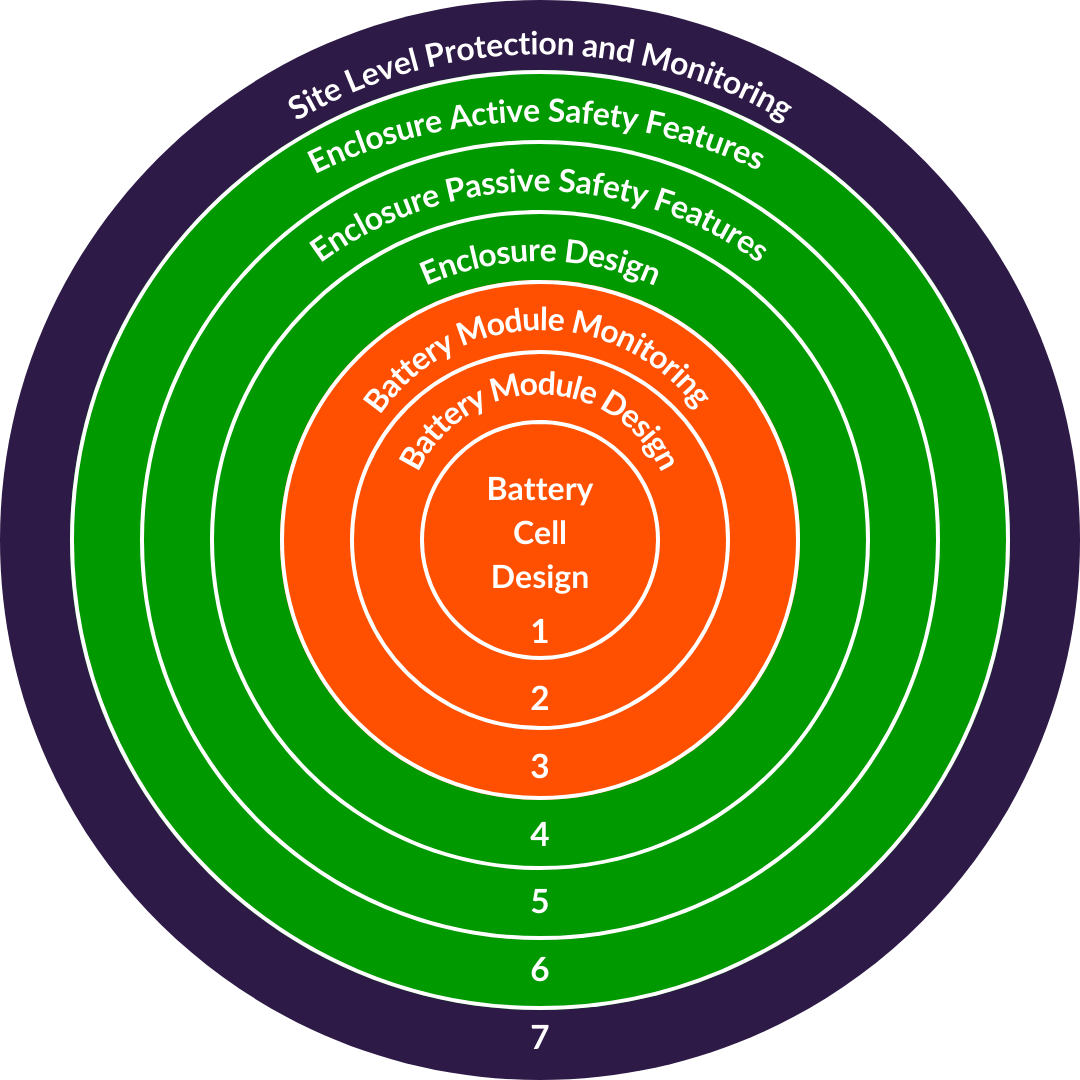

Seven layers of safety

Our BESS systems are protected by seven layers of safety design criteria, starting well before construction begins with proactively vetting our equipment. During construction, we install additional safety features, which help us monitor the project 24/7 during its operational life.

- Battery Cell Design: Each will be individually enclosed and extensively tested to validate cell safety, performance and quality.

- Battery Module Design: Tested to UL9540A where no propagation of fire to adjacent modules occurs even under extreme thermal conditions.

- Battery Module Monitoring: Battery Management System (BMS) continually monitors battery cells to ensure normal operation, detect any abnormalities and take remedial actions in the event of an issue, such as disconnecting or shutting down specific battery modules

- Enclosure Design: Designed with non-combustible materials and able to withstand seismic activity, heavy weather and high winds.

- Enclosure Passive Safety Features: Noncombustible enclosure walls, deflagration panels, enclosure separation, short circuit protection.

- Enclosure Active Safety Features: UL-rated enclosures that have completed rigorous safety testing and are equipped to actively manage thermal conditions.

- Site Level Protection and Monitoring: On-site personnel and 24/7/365 command centers that continuously monitor the condition of every energy storage system enclosure

Diligence in equipment procurement & testing

Designing a battery energy storage system starts with selecting our equipment—the batteries themselves, as well as the enclosures that hold them. Lightsource bp’s engineering and procurement teams perform rigorous qualification and review of our partners to vet for compliance with applicable standards and procedures.

For example, all battery technologies deployed by Lightsource undergo large scale fire testing using the UL 9540A procedures to validate what would happen in the unlikely event of a fire. This includes testing at every level, from the smallest individual battery cell to the BESS installation as a whole. Enclosures are typically equipped with a liquid cooled system that uses a combination of chiller and HVAC to keep batteries within certain temperature ranges. If an elevated temperature is reached, the system will automatically be shut down.

24/7 monitoring & site control

Once a battery energy storage system comes online, the facility is watched closely by both on-site personnel and 24/7 remote monitoring. Each block of batteries has a Battery management System as its “brains,” a command center that tracks the condition of every single system enclosure.

An additional control system called SCADA (supervisory control and data acquisition) enables further real-time monitoring of the full system. At Lightsource bp, we ensure the SCADA system is up and running 24/7 with backup power integrated as an additional safety measure.

Visual and audio alarm systems will trigger in the unlikely event of an emergency. Site personnel will have access to an emergency shutoff control feature.

Partnerships for emergency preparedness

From the time we start planning a storage project, through construction and operations, Lightsource bp works with regional governmental authorities such as the local fire marshal to understand their requirements and concerns as they may relate to battery safety. Such requirements and expectations are ultimately included in our design, resulting in safe and reliable energy storage systems.

We also work with local fire departments to provide specialized training on battery fire events and ensure that a response plan is in place for the unlikely case of an emergency.

Battery energy storage system (BESS) FAQs

We have gathered a list of frequently asked questions (FAQs) to help you learn more about battery energy storage, such as:

- How does storage reduce energy costs?

- Are utility-scale battery energy storage systems safe?

- What happens when batteries reach their end of life?